Ensuring Quality and Precision: CNC Process and Test Reports for Maxicrane’s Aluminum Components

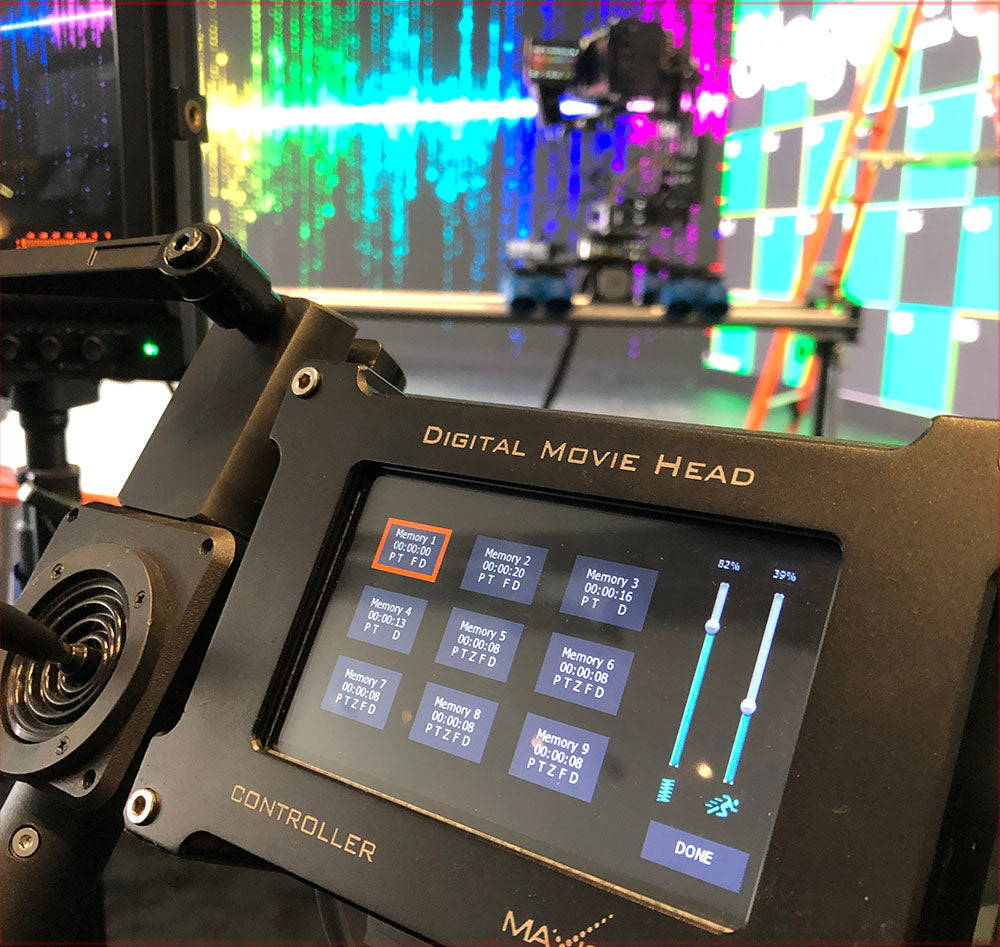

At Maxicrane, we are committed to delivering the highest quality products, including our renowned Scarab Dollies and Ostrich systems. A critical part of this commitment involves rigorous quality verification processes during the CNC machining of aluminum components, as well as comprehensive test reports that ensure these materials meet our stringent standards.

The Importance of Quality in CNC Machining

Computer Numerical Control (CNC) machining is a precise manufacturing process where pre-programmed software controls the movement of machinery and tools. For our products, this means that every cut, hole, and contour is executed with exact precision, resulting in components that perfectly fit together and perform reliably under demanding conditions.

CNC Process for Aluminum Components

- Material Selection: We start with high-grade aluminum alloys known for their strength, durability, and lightweight properties. These alloys are selected based on their specific mechanical properties that suit the performance requirements of our motion control systems.

- Precision Machining: Utilizing state-of-the-art CNC machines, we manufacture parts with tolerances as tight as ±0.01 mm. This high level of precision ensures that each component fits seamlessly, enhancing the overall performance and longevity of our products.

- Surface Finishing: After machining, components undergo various finishing processes such as anodizing or powder coating. These finishes not only improve the aesthetic appeal but also enhance corrosion resistance and durability.

- Quality Control: Throughout the CNC machining process, we implement rigorous quality control measures. This includes regular inspections using Coordinate Measuring Machines (CMM) to verify dimensions and tolerances, ensuring each part meets our exact specifications.

Test Reports and Verification

To ensure the reliability and quality of our aluminum components, we conduct extensive testing and provide detailed reports. These reports serve as a testament to our commitment to quality and are available for review by our clients.

- Material Test Reports (MTR): These reports detail the composition and mechanical properties of the aluminum used. They include information on tensile strength, yield strength, elongation, and hardness, ensuring the material meets the required standards.

- Dimensional Inspection Reports: Using CMM and other precision measurement tools, we generate reports that document the dimensions of each component. These reports confirm that parts are manufactured within specified tolerances.

- Surface Finish Reports: These reports verify that the surface finish of each component meets our rigorous standards, ensuring both aesthetic quality and functional performance.

- Performance Testing: We conduct performance tests on critical components to simulate real-world conditions. This includes stress testing, load testing, and fatigue testing to ensure each part can withstand the demands of its intended use.

Conclusion

At Maxicrane, quality and precision are at the core of our manufacturing process. Through advanced CNC machining and comprehensive testing, we ensure that our Scarab Dollies and Ostrich systems are built to the highest standards. Our detailed test reports provide transparency and assurance to our customers, demonstrating our unwavering commitment to excellence.

By investing in high-quality materials, precise manufacturing processes, and rigorous testing, we deliver products that not only meet but exceed industry standards, providing our clients with reliable and innovative motion control solutions. For more detailed information on our quality verification processes and test reports, visit:

https://www.kaiseraluminum.com/

https://mitutoyo.com/products/coordinate-measuring-machines/

Leave a comment